In one of my favorite episodes of The Big Bang Theory that aired 10 years ago, Raj and Howard buy a used 3D printer for $5,000. After three hours of waiting to print a computer-modeled whistle, the duo decides to design and print personalized action figures, convinced that they were reclaiming the entire manufacturing process. Needless to say, the “bang” for their buck does not go over well with Howard’s wife and he is forced to sell his share of the machine back to Raj.

While the premise of two friends using a 3D printer to make whatever they could imagine was a catalyst for comedy and over-exaggerated for television viewing audiences, the concept isn’t so far-fetched. The original idea behind 3D printing, which was brought to life in the early 1980s, was that any object could be made by layering material dispensed through a nozzle, just like inkjet printers dropping ink onto paper.

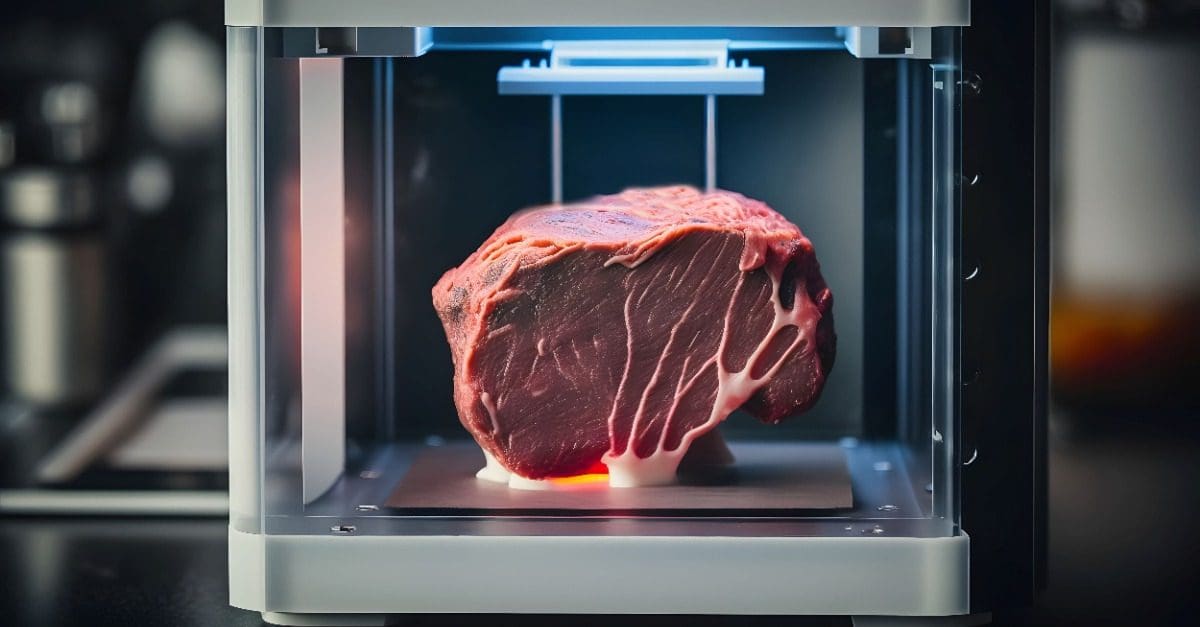

Today, the process of 3D printing has moved beyond just polymers and plastics. Scientists are using 3D printers to print human tissue, prosthetics, aircraft, automobiles, and even emergency shelters in disaster areas. The next big leap in this technology could be 3D-printed food.

The global 3D food printing market is expected to reach $1.941 billion by 2027, up from $201 million in 2022.1 But is the technology really expected to reach mainstream suburban kitchens?

The creation of 3D-printed food technology

Associate Professor Hod Lipson at Cornell University’s Mechanical and Aerospace Engineering Department led a research team that developed the Fab@Home 3D printer in 2006. The group started experimenting with food fabrication by loading the printer’s dispensers with liquid-based foods in 2007. David Arnold, the director of culinary technology at the French Culinary Institute in Manhattan, New York, began testing the new 3D printing tech in 2009.

The original technology could only print through a syringe, so the shape of the creations was stringy, resembling noodles. But the chefs at the institute experimented with using it to write with icing, print cake frosting, process cheese, and create simple chocolate designs.

By 2014, the US Army was looking into ways to use 3D printers to produce military rations. The Natick Soldier Research, Development, and Engineering Center, led by food technologist Lauren Oleksyk, began experimenting with nutrient-rich rations that could be modified to meet each soldier’s unique dietary needs. NASA has also explored the idea of printing food for space missions.

Advances in 3D food printing

A team of engineers at the Creative Machines Lab at Columbia University, including Hod Lipson, who was mentioned previously in his connection to the creation of 3D printed food technology, challenged themselves to design, print, and laser-cook a seven-layer cheesecake, seemingly setting a record for the number of ingredients used in a food printed product.2 Using graham crackers, peanut butter, Nutella, banana puree, strawberry jam, cherry gel, and frosting, it took several failed recipes to get the correct structure. However, the result resembled a slice of cake and according to the study’s lead author, Jonathan Blutinger, “tasted pretty sweet, in more ways than one.”3

Two Israeli companies, Redefine Meat and SavorEat, are also turning heads by using 3D food printing technology to create plant-based meat. Using plant-based cellulose, pea proteins, legumes, and grains, these companies are printing steaks and burger patties that have similar muscle texture, flavor, and color to real meat. SavorEat has already filed patent applications for the 3D food production method in the United States, Europe, and Australia.4

So many questions…

While it’s clear that 3D-printed food is evolving, additional questions arise. What is the 3D printing process like, how safe is it, and what are the costs? Let’s answer those questions.

How does it work?

Essentially, printing 3D food works in much the same way as traditional 3D printing. A digital design or model is created and uploaded into the 3D food printer. Edible materials like dough, chocolate, pureed fruits, and even raw meats are extruded through a nozzle to create the desired design, layer by layer.

A couple of different methods are used in printing food, which follow similar principles to plastic printing. Fused deposition modeling (FDM) uses a heater nozzle that melts the food material before extracting it. Binder jetting uses an edible liquid binding agent with edible powders, like sugar or chocolate, to create the final products.

Do 3D food printers cook the food?

Most current market 3D food printers are designed to create shapes and designs with foods that don’t need cooking before consumption. If cooking is required, it would need to be handled separately after the printing process. However, technology is advancing rapidly, with some 3D food printers offering a hotplate mechanism to cook the printed food, as well as laser technology and radiation, similar to a microwave.

How long does it take to print food?

It took the engineers at Creative Machines Lab 30 minutes to complete the printing process for their cheesecake.5 Simple designs may only take minutes to print, while more intricate models could take more than 45 minutes.6

Is 3D-printed food safe?

The foods used in 3D printers are real foods, just in a paste or liquid version, and would have met whatever food guidelines are required. However, the maintenance of the machine printer itself can cause those foods to become unsafe.

Dangerous bacteria, like E. coli and Salmonella, can grow in the tiniest of places within the printer if not cleaned and maintained, much like any other household appliance used for cooking. Using harsh chemicals, like bleach, would never be an option for eliminating potential germs, as residual chemicals could impact the food, making it unsafe to consume.

Are 3D food printers affordable?

As with all technology, prices will vary based on features, quality, and availability. A basic model for at-home chefs could cost upwards of $500. An advanced 3D food printer for home use will likely reach the $1,000 price range. Commercial businesses that need a more sophisticated machine that can reach high nozzle temperatures may have to pay over $5,000.7

The future of 3D food printing

Today, food 3D printers are mostly used in gourmet dining, in places like Michelin-rated kitchens or fancy bakeries. 3D food printing allows chefs to create intricate shapes and structural designs that can be precisely replicated. To be a viable industry for the average consumer, 3D food printing needs the help of supporting industries such as food cartridge manufacturers, downloadable recipe files, and a social or educational environment where at-home food preparers can share their experiences and recipes.

Looking to the future, people with dietary restrictions, babies and toddlers, nursing home dieticians, those who have swallowing or digestive disorders, and athletes could all benefit from 3D food printing techniques to make meal planning easier and offer nutritional control. More advanced 3D-printed food systems that also use high-energy targeted light for heating could also make cooking more automated and cost-effective.

References

1 https://www.researchandmarkets.com/reports/5585399/global-3d-food-printing-market-by-vertical/

2 https://www.nature.com/articles/s41538-023-00182-6#ref-CR15

3 https://www.usatoday.com/story/news/nation/2023/03/21/food-future-3-d-printed-cheesecake-dessert/11514028002/

4 https://www.timesofisrael.com/israels-savoreat-to-launch-us-pilot-offering-3d-printed-plant-based-burgers/

5 https://www.smithsonianmag.com/smart-news/scientists-3d-printed-a-slice-of-cake-180981862/

6 https://all3dp.com/2/3d-printed-food-3d-printing-food/

7 https://www.foodsafetynews.com/2022/10/3d-food-printers-are-already-a-science-fact-not-far-fetched-science-fiction/