In today’s fast-paced, technology-driven world, the demand for innovation in manufacturing laboratories is at an all-time high. These labs serve as the backbone of quality control, product development, and process optimization, making their efficiency critical to the success of manufacturing businesses. By driving innovation through smart technology, automated systems, and data-driven solutions, manufacturing labs can not only improve operational efficiency but also significantly reduce costs, enhance product quality, and boost competitiveness.

In this article, we’ll explore how innovation is reshaping manufacturing laboratories, offering real-world examples, impressive statistics, and insights into the potential savings and long-term benefits.

The Role of Manufacturing Laboratories in Modern Industry

Manufacturing laboratories are tasked with various responsibilities, including testing raw materials, analyzing finished products, and validating production processes. In industries such as pharmaceuticals, chemicals, automotive, and consumer goods, labs ensure that each product meets stringent regulatory standards and customer expectations.

The increasing demand for precision, speed, and flexibility in these labs has sparked a shift towards adopting innovative technologies such as Laboratory Information Management Systems (LIMS), automation, and artificial intelligence (AI). These technologies not only enhance operational performance but also offer greater agility, allowing companies to adapt to rapidly changing market conditions.

Real-World Example: Automation in Pharmaceutical Manufacturing Labs

Pharmaceutical companies face high stakes in product testing and validation due to the rigorous requirements of regulatory bodies like the FDA. In such a demanding environment, laboratory automation can be a game-changer. For example, Pfizer’s deployment of automated testing systems in their manufacturing labs enabled them to increase testing speed by 30%, reduce human error, and maintain compliance more efficiently.

By integrating automation into the testing process, Pfizer was able to handle large volumes of data, streamline workflows, and shorten product release cycles—saving the company millions annually while maintaining high standards of safety and quality.

Key Innovations Driving Manufacturing Lab Efficiency

1. Laboratory Information Management Systems (LIMS)

LIMS is at the forefront of innovation in manufacturing labs. These systems provide a centralized platform for managing lab workflows, tracking samples, automating data entry, and ensuring compliance with industry standards.

Fact:

According to a 2023 report by MarketsandMarkets, the global LIMS market is projected to grow from $1.5 billion in 2021 to $2.9 billion by 2026, driven by the need for automation, better data management, and regulatory compliance in manufacturing and pharmaceutical sectors.

By implementing a LIMS solution, manufacturing labs can optimize their operations, reducing the need for manual input and improving data accuracy. This can lead to significant savings in terms of labor costs and time. For instance, a typical manufacturing lab could save up to 25% of its operational costs by transitioning from manual processes to an integrated LIMS.

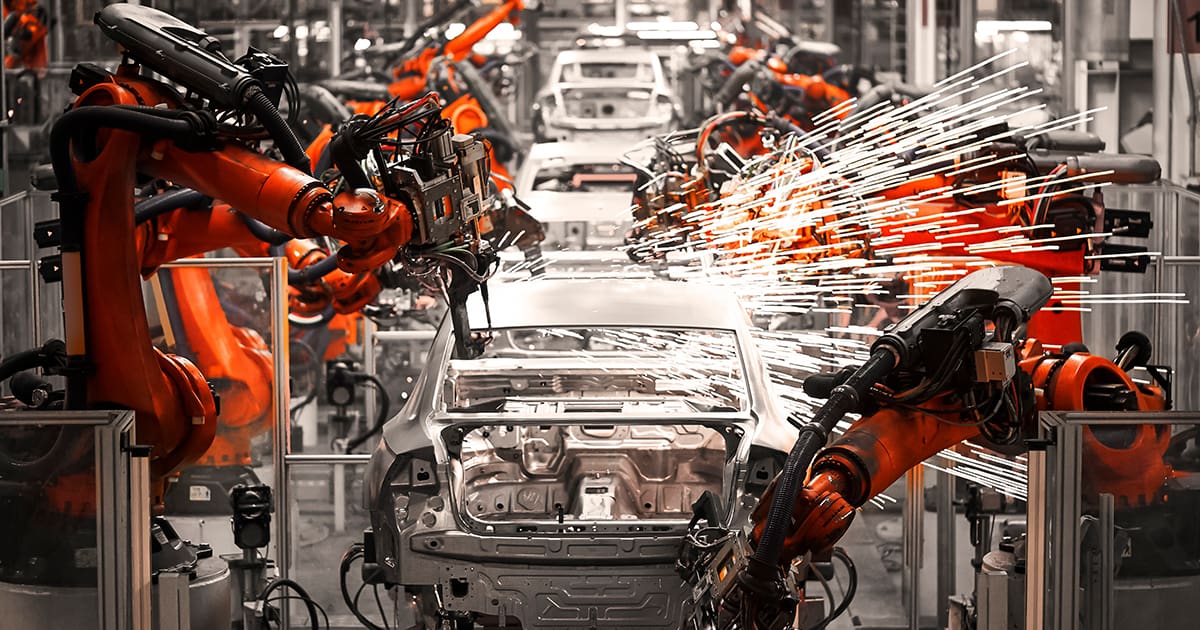

2. Automation and Robotics

Automation in manufacturing labs ranges from robotic sample handlers to automated analytical instruments that run tests without human intervention. This technology can dramatically improve productivity, reduce errors, and enhance safety.

Real-World Scenario: Automotive Industry

In the automotive industry, material testing is crucial for ensuring durability and safety. A leading automotive manufacturer adopted robotic arms to handle repetitive sample testing, which resulted in a 40% reduction in testing time. By freeing up technicians from mundane tasks, they could focus on more complex problem-solving, ultimately improving innovation in the product development phase.

3. Artificial Intelligence and Machine Learning

AI and machine learning are transforming how data is analyzed in manufacturing labs. These technologies can quickly analyze vast datasets, identifying patterns and anomalies that would take humans days or even weeks to process.

Example: Chemical Processing Labs

In chemical processing labs, AI-powered systems are used to monitor and predict the outcome of experiments in real time. By analyzing variables such as temperature, pressure, and concentration, AI systems can recommend optimal conditions for the desired chemical reaction. This approach can reduce the number of failed experiments, saving both time and raw materials, and boosting productivity by up to 50%.

4. Cloud-Based Solutions

The cloud is enabling manufacturing labs to store and access data from anywhere in the world. Cloud-based LIMS and other lab software allow teams to collaborate in real time, share insights, and ensure that all data is securely backed up.

Fact:

A 2022 study by Gartner found that companies using cloud-based LIMS reported a 35% improvement in data accessibility and a 20% reduction in IT-related costs, as they no longer needed to maintain on-site servers.

For multinational companies with labs spread across various locations, cloud-based systems are vital for harmonizing data, ensuring all labs are following the same procedures, and fostering global collaboration.

Potential Savings Through Lab Innovation

Innovation in manufacturing laboratories doesn’t just enhance operational performance; it also translates into significant cost savings. Here are some potential savings areas:

1. Labor Efficiency: By automating routine tasks, labs can reduce the number of hours spent on manual work by up to 50%. This not only decreases labor costs but also minimizes human errors, leading to fewer reworks and product recalls.

2. Faster Time-to-Market: Innovations like LIMS and AI can help labs speed up testing and analysis, allowing products to reach the market faster. In highly competitive industries such as pharmaceuticals, shaving just a few weeks off a product development timeline can mean millions in additional revenue.

3. Resource Optimization: AI and machine learning can optimize experiments, reducing the amount of raw materials wasted during the testing phase. For example, a manufacturing lab that produces chemical compounds might save 15-20% on material costs by using AI to predict the most efficient test conditions.

4. Compliance and Reduced Risk: Regulatory non-compliance can result in costly fines and production delays. By using digital systems like LIMS, labs can automate compliance reporting, ensuring they meet all required standards and reducing the risk of penalties.

Conclusion: The Future of Manufacturing Laboratories

As the pace of technological advancement continues to accelerate, manufacturing laboratories must embrace innovation to remain competitive. Whether it’s through automation, AI, cloud-based solutions, or LIMS, the benefits of adopting these technologies are clear: increased efficiency, cost savings, faster product development, and improved compliance.

For companies looking to drive innovation in their labs, the time to act is now. By investing in the right technologies, manufacturing labs can secure their place at the forefront of the industry, ensuring their products not only meet but exceed expectations in today’s demanding marketplace. The future of manufacturing labs is one where technology and human ingenuity work together seamlessly, driving success in a complex, evolving world.

Accelerate Your Lab's Success & Experience LabLynx

"*" indicates required fields

Explore the LabLynx Suites

LIMS Suite

Seamless Sample and Workflow Management

The LabLynx LIMS Suite empowers laboratories with the tools needed to manage samples, workflows, compliance, and more in one centralized system. It’s the backbone for labs seeking efficient, reliable, and scalable management solutions.

ELN Suite

The LabLynx ELN Suite offers a modern approach to managing lab data and experiments. With its secure, intuitive platform, your team can record, store, and collaborate effortlessly, supporting innovation every step of the way.

Lab Automation

Automate for Efficiency and Growth

Streamline operations and boost productivity with the LabLynx Lab Automation Suite. Designed for labs ready to embrace advanced automation, this suite integrates systems, instruments, and workflows to deliver efficiency at scale.