This content has been archived. It may no longer be relevant

The recent LabLynx blog article “How Supply Chain Issues Have Impacted Laboratories” focused on the impact of COVID-19 on the supply of diagnostic testing needs like specimen tubes, personal protective equipment, and reagents. While demand for these supplies remains high, clinical diagnostic labs and healthcare testing facilities are not the only businesses impeded by supply shortages in the wake of the pandemic.

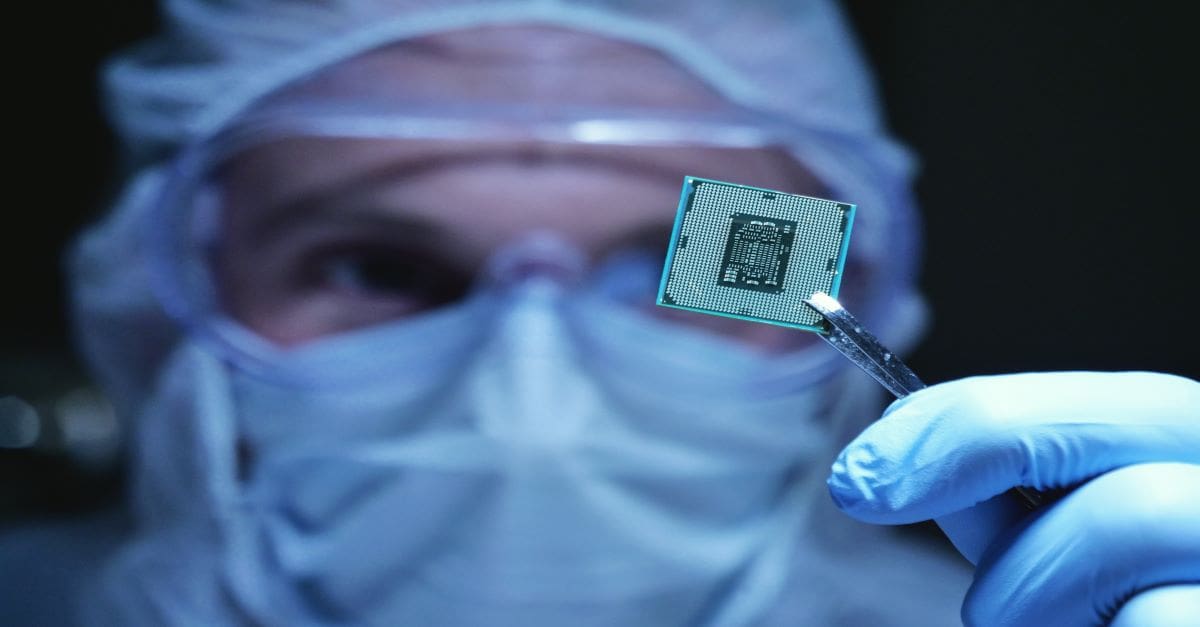

Nearly every piece of electronic equipment used in the world relies on semiconductors (also referred to as integrated circuits or microchips), from cell phones and microwaves to pacemakers and automobiles. A global battle is being waged to boost the manufacturing of microchips and profit from the demand from nearly every market segment.

What caused the microchip shortage?

The single underlying cause of the global semiconductor shortage is COVID-19. Among the virus outbreaks, labor shortages, country-wide lockdowns, and political uncertainties, the supply chain of microchips was severely disrupted and has yet to recover.

The onset of the pandemic caused businesses to temporarily close or shut down completely and the world’s population to retreat. Demand for all goods and services dropped instantly and substantially. But the initial shock and fear phase was soon followed by the work- and school-from-home phase that brought a spike in demand for technology like PCs, tablets, webcams, game consoles, and graphic cards, which microchip manufacturers neither expected nor could keep up with.

The automobile industry was also hit hard by the shortage of microchips. When the pandemic started, travel restrictions and work-from-home options meant plummeting demand for personal vehicles. After the vaccine release, carmakers saw demand increase, but chip factories were already overwhelmed with orders and focused on producing high-end chips that automakers didn’t need. The low-power semiconductors used for power windows or cabin temperature control took a backburner to the more expensive and complex ones needed for computers and cell phones.

The inability to meet the demand from the manufacturing side and the bottleneck of shipping issues—like shipping barges sitting idle at sea for weeks on end, waiting to unload their containers—has perpetuated the semiconductor shortage and brought the need to propel microchip manufacturing to the forefront of many worldwide governments, including the European Union (EU), United States (US), and China.

EU, US, and China invest in semiconductor manufacturing

EU

In February 2022, the European Commission approved the European Chips Act, which added €15 billion (~$18 billion) to an existing €30 billion (~$36 billion) in public investments for STEM-focused (science, technology, engineering, and mathematics) programs. In a statement released by President von der Leyen, the Chips Act has two main goals, “in the short term, to increase the resilience to future crises by anticipating and thus avoiding supply chain disruptions,” and in the mid-term, “make Europe an industrial leader in this very strategic market.”1

The EU currently boasts nine percent of the global microchip market, and the EU Commission is hopeful the additional funding from the Chips Act will increase their market share to 20 percent by 2030.1 Europe plans to focus on research, building advanced manufacturing facilities, supporting start-up companies interested in joining the integrated circuit market, and becoming more self-sufficient.

US

Not to be outpaced by the EU, US President Joe Biden signed into law the CHIPS and Science Act in August 2022, which directs $280 billion in spending over the next 10 years, the majority of which is marked for scientific research and development, as well as commercialization. However, the CHIPS Act also provides US semiconductor makers with $52.7 billion in funding and subsidies over the next five years to increase microchip manufacturing.2 This act supports the administration’s Critical Supply Chain Resiliency Program and the Made in America effort.

The CHIPS Act offers a $3 billion discount to build new, modern fabrication facilities (fabs) that might otherwise cost $10 billion (essentially a 30 percent discount).3 At least seven major semiconductor companies plan to build more than $200 billion in fabs in the coming years.4 Intel announced plans for two new microprocessor plants in Ohio, which should start producing chips in 2026.5

Historically, the US dominated the global semiconductor industry, garnering a 37 percent market share in 1990. However, in the past 30 years, that share has dropped to about 12 percent, with Taiwan (22 percent), South Korea (21 percent), Japan (15 percent), and China (15 percent) accounting for 73 percent of all microchip manufacturing globally.6

While the US recognizes that it is not possible to move the whole electronics industry to the states, the goal is to rebalance the global supply chain and lessen the United States’ dependence on imported microchips from China and other countries in Asia.

China

Speaking of China, in a report released on December 13, 2022, China announced a one trillion Yuan ($143 billion) plan to increase its semiconductor manufacturing as early as Q1 2023. The initiative would provide subsidies and tax credits and encourage increased research and production. Over five years, this is expected to be one of China’s largest investments.7

The response not only combats the efforts of the US and EU to take market share from China but also Taiwan. The Taiwanese electronics manufacturer, Foxconn, announced it would be investing $500 million to build a microchip manufacturing plant in India, where Apple is expected to add an iPhone production hub by 2025. Apple currently relies on Chinese-produced chips for their smartphones.7

How long will the microchip shortage last?

More chips have become available in the latter half of 2022 due to waning demand for PCs, smartphones, and consumer electronics. However, it will likely take a good portion of 2023 to absorb the impact of a shortage that has lasted nearly two years.

Automobile manufacturers may have to wait a little longer to see recovery. Microchip manufacturers will need to convert from high-end semiconductors to those suited for the auto industry, but only when it’s profitable to do so. Then it will take time to fulfill back orders and rebalance the manufacturing process between low- and high-power chips.

A lesson to be learned in preparedness

There are many lessons to be learned from the pandemic, as well as the subsequent supply chain shortages and shipping delays, that apply to manufacturing businesses and any business, including laboratories across all industries. First and foremost, is to have a preparedness plan. Below are a few tips:

- Don’t assume you will have product resources available in a time of need.

- Maintain a strong inventory of all necessary products and monitor that inventory frequently.

- Investigate multiple supplier/vendor options.

- Keep lines of communication open.

If your laboratory needs assistance with inventory management, consider a laboratory information management system (LIMS). The LabLynx ELab LIMS for Manufacturing not only manages your samples, testing workflows, and results, but ELAB LIMS also provides inventory management to track resources and supplies, monitor inventory, gauge stock levels, forecast reordering, and provide alerts when quantities are low.

Contact sales@lablynx.com to learn more or visit our website at www.lablynx.com.

References

1 https://ec.europa.eu/commission/presscorner/detail/en/statement_22_866/

2 https://www.mckinsey.com/industries/public-and-social-sector/our-insights/the-chips-and-science-act-heres-whats-in-it/

3 https://www.cnet.com/tech/computing/global-chip-shortage-gives-us-manufacturing-a-boost/

4 https://www.fierceelectronics.com/electronics/does-chips-act-end-chip-shortage-any-time-soon-no-actually/

5 https://www.kbb.com/car-news/microchip-shortage-still-limiting-car-production/

6 https://www.aspistrategist.org.au/seismic-shifts-underway-in-global-semiconductor-market-as-us-accelerates-decoupling-from-china

7 https://www.foxbusiness.com/markets/china-us-chip-battle-heats-up-beijing-prepares-spend-143b-boost-manufacturing-report/