Every product you use—from the medicine in your cabinet to the food on your plate—passes through the meticulous oversight of QA/QC laboratories. These unsung heroes work behind the scenes to ensure safety, quality, and compliance, setting the stage for consumer trust and industry success. But as expectations grow and regulations tighten, how can QA/QC labs stay ahead? The answer lies in adopting cutting-edge lab management solutions that simplify operations, reduce errors, and enhance productivity.

Whether you’re monitoring production lines, testing raw materials, or ensuring product consistency, innovative solutions are redefining what’s possible in the QA/QC space.

The Pressure Is On: Challenges Facing QA/QC Labs Today

Modern QA/QC laboratories are at the crossroads of efficiency and precision. Their mission? To balance ever-growing demands with uncompromising accuracy. Yet, challenges persist:

- Massive Data Volume: Managing growing datasets while maintaining accuracy and accessibility.

- Stringent Compliance: Keeping pace with evolving regulatory requirements like ISO 17025, GMP, and FDA standards.

- Time Constraints: Balancing quick turnarounds with detailed, thorough testing processes.

- Human Error Risks: Manual processes leave room for inaccuracies that can compromise results.

- Complex Workflows: Coordinating multiple tests, instruments, and team members without bottlenecks.

These challenges demand a smarter, more streamlined approach to lab management—one that brings order to chaos and empowers teams to deliver results that exceed expectations.

How QA/QC Lab Management Solutions Drive Transformation

Lab management solutions designed for QA/QC operations provide an essential foundation for meeting these challenges head-on. Their versatility and innovation enhance every stage of the testing process.

1. Complete Sample Lifecycle Oversight

From the moment a sample enters the lab to the final analysis, these solutions ensure traceability and transparency. Each sample is tracked with unique identifiers, minimizing mix-ups and ensuring accurate reporting.

2. Compliance at the Core

With built-in tools that support ISO, FDA, and GMP compliance, QA/QC solutions simplify audit preparation. Features like automated documentation, electronic signatures, and audit trails safeguard data integrity.

3. Workflow Automation

Automated workflows remove repetitive manual tasks, allowing staff to focus on analysis and decision-making. Test scheduling, alert notifications, and data uploads are streamlined to eliminate inefficiencies.

4. Customizable Dashboards and Insights

Interactive dashboards present real-time operational insights, empowering lab managers to make proactive decisions. Custom reports provide a snapshot of key metrics, helping teams stay ahead of challenges.

5. Seamless Integration

Modern systems integrate effortlessly with lab instruments, enterprise resource planning (ERP) software, and other tools, creating a unified ecosystem for data management and analysis.

Real-World Applications of LIMS for QA/QC Labs

Pharmaceuticals: Precision in Every Dose

In the pharmaceutical industry, rigorous testing ensures that medicines meet safety and efficacy standards. A LIMS streamlines stability testing, tracks sample data, and automates report generation, reducing errors while improving efficiency.

Food and Beverage: Protecting Consumer Trust

For food manufacturers, consistency is key. A lab management solution helps monitor raw materials, track batch testing, and ensure the final product meets safety and quality requirements, reducing waste and increasing consumer confidence.

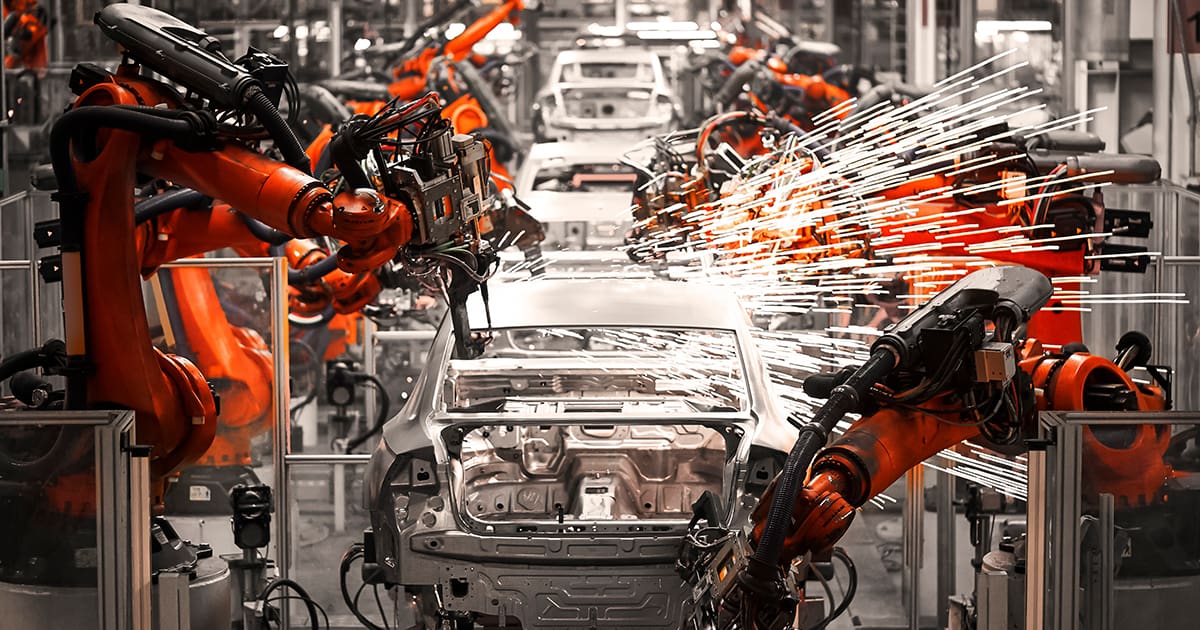

Automotive: Meeting Stringent Safety Standards

Automotive parts require durability and precision. With a LIMS, labs can manage material testing workflows, monitor quality audits, and ensure compliance with safety regulations, enabling manufacturers to maintain their competitive edge.

Cosmetics: Ensuring Safety and Consistency

From raw ingredient testing to final product verification, a LIMS enables cosmetics labs to streamline processes, track results, and ensure compliance with regulatory standards, supporting brand reputation and customer satisfaction.

Why QA/QC Labs Need a Modern Management System

Implementing advanced lab management solutions offers a wealth of benefits, transforming how QA/QC labs operate:

- Error-Free Data Handling: Automation ensures every detail is accurate and accessible.

- Faster Turnaround Times: Streamlined workflows accelerate testing and reporting.

- Compliance Confidence: Built-in tools simplify adherence to even the most rigorous standards.

- Actionable Insights: Real-time dashboards provide clarity, empowering informed decision-making.

- Scalability: These solutions grow with your lab, adapting to evolving needs.

The Road to Excellence Starts Here

For QA/QC labs ready to move beyond the constraints of outdated systems, the future is bright. Modern lab management solutions offer more than just operational support—they empower labs to innovate, thrive, and redefine their role in ensuring quality and safety across industries.

Elevate your lab’s potential with tools that deliver precision, efficiency, and unmatched performance. The journey to excellence starts today. Explore how these solutions can revolutionize your lab and position it as a leader in quality and compliance.

Quality isn’t just a goal—it’s a commitment. Let modern lab management solutions help you achieve it.